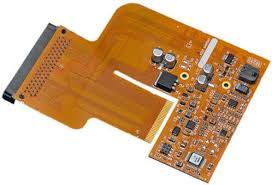

Flexible Printed Circuit Board

RoHS, or Restriction of Hazardous Substances is a European Union directive that limits the use of certain chemicals during the production of electrical equipment. This directive impacts the entire supply chain for EEE and PCB manufacturers. The directive is amended frequently and it is important for PCB manufacturers to stay informed about these changes to ensure compliance.

The first step is to make sure that all materials used in the manufacture of a circuit board are RoHS compliant. This includes the substrate material, soldering process and surface finishes. In addition to this, the component selection must also be RoHS compliant. There are several options for RoHS compliant components and it is critical that they are chosen for the right applications.

As a result of the RoHS directive, many manufacturers have chosen to eliminate certain substances from their base materials. Currently, the majority of the common substrates are RoHS compliant, including FR-4, PTFE and a variety of specialty materials. It is important to note that the RoHS directive does not limit the number of components that can be used in a circuit board, but the individual parts must be compliant.

RoHS Compliance in Flexible Printed Circuit Board

For a flexible printed circuit board to be fully RoHS compliant, the soldering process must be lead-free. This means that the solder alloy must be copper, tin and silver and the soldering process must be controlled to ensure that no hazardous substances are released. This is an important step because if any lead is used in the assembly of a circuit board, it will leach out into the finished product and affect its lifespan.

The RoHS regulations limit the usage of 10 toxic heavy metals in the manufacturing of electronic equipment. These restrictions are designed to reduce toxicity risks for human health and the environment. They also help to improve recycling and disposal efforts and reduce environmental waste.

Aside from the toxicity issues, these regulations also protect people who work in the electronics industry by reducing the exposure to these chemicals. These workers often handle the products while on conveyer belts and are exposed to solder fumes, which can cause a variety of respiratory diseases, such as pulmonary fibrosis.

The benefits of a RoHS-compliant PCB are numerous and include reduced costs, improved reliability and environmentally friendly manufacturing processes. Moreover, the regulations are strictly enforced and the penalties are steep, which makes it difficult for companies to flout these rules. It is a good idea for manufacturers to have clear policies in place and train employees on how to adhere to these standards.

While the transition to a RoHS-compliant circuit board requires a significant investment, it is well worth it in terms of ensuring a safe and healthy workplace and a high-quality product. To help make the transition easier, manufacturers can use a range of tools and resources available to them, including OrCAD from Cadence. This software can help them identify RoHS-compliant components, verify that their manufacturing partners are compliant and manage the design process to meet RoHS requirements.